How to Create a Rock-Solid Woodworking Bench (Step-by-Step Guide)

A good woodworking bench is the heart of any workshop. Whether you're a hobbyist or a professional, a solid, well-designed bench gives you the stability and features you need to work efficiently and safely.

In this blog, we’ll walk through how to build a traditional, sturdy woodworking bench with a thick hardwood top, strong base, and optional vise support. Diagrams and visual guides are included to help every step of the way

🧰 Materials & Tools

Materials:

2x Hardwood butcher block or laminated hardwood boards for benchtop

4x4 or 6x6 posts for legs

2x6 boards for stretchers

Wood glue

Wood screws / lag bolts

Vise (optional)

Drawer slides & plywood (optional for storage)

Tools:

Circular saw or table saw

Drill/driver

Clamps

Chisel

Sander

Measuring tape

Square

Wood finish (e.g., linseed oil or polyurethane)

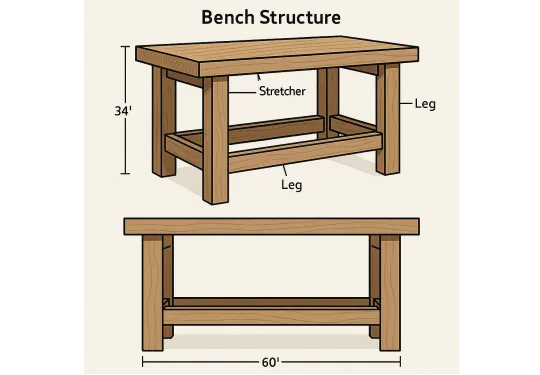

Here’s a basic diagram of the bench structure:

📐 Bench Design Overview

Dimensions:

Height: ~34" (adjust to your comfort)

Top: 60" x 24" x 2.5"

Legs: 4x4 posts

Stretchers: 2x6 boards

Click here to find the best woodworking plans for your next project!

Step 1: Build the Base Frame

Cut the Legs: Cut 4 legs from your 4x4 or 6x6 posts (around 32–34” long).

Cut the Stretchers: Use 2x6 boards to connect the legs — two for the top and two for the lower shelf support.

Join the Frame: Use lag bolts or wood screws to attach the stretchers to the legs. Reinforce with wood glue.

Add Bottom Shelf (Optional): Add a plywood panel across the lower stretchers for tool storage.

Step 2: Prepare and Install the Benchtop

Glue Up Boards (if not using a pre-made top): Clamp multiple hardwood boards edge-to-edge using glue.

Sand Smooth: Use a belt or orbital sander to flatten and smooth the top.

Attach Top to Base: Secure the benchtop to the base using screws from underneath. Ensure it's centered and square.

Step 3: Add Vise (Optional)

Choose either a front vise or end vise.

Use a Forstner bit and chisel to create mounting recesses for the vise hardware.

Attach securely to the front corner of the bench.

Click here and gain access to thousands of woodworking plans with step by step guides

Step 4: Finish the Bench

Apply linseed oil, tung oil, or polyurethane.

Let it cure for 24–48 hours.

Optionally, add dog holes, tool tray, or T-track system later on.

🗂️ Optional Add-ons

Drawers: Use ¾" plywood and metal slides to install a drawer system underneath.

Power Strip: Mount a power strip to the side for easy access to tools.

Casters: Add lockable casters if you need mobility.

🧪 Final Thoughts

A handmade woodworking bench will outlast anything you can buy in a store, and you'll build priceless skills in the process. Don’t rush the process — take your time with joinery and finishing, and you’ll end up with a bench that’s both functional and beautiful.